MS-96 Total Quality Management Test Paper

MBA - Master of Business Administration

Note: Attempt any three questions from Section A. Section B is compulsory and carries 40 marks.

1. Critically examine, with examples, the following statements:

(a) Total quality is too important to be considered as subsidiary

to profit." Do you agree? Why or Why not?

(b) "Quality and cost are complimentary and not conflicting

business objectives."

2. Examine the role and responsibility of top management of an organisation in achieving centred focus on strategic planning.

3. (a) Discuss the primary applications of control charts.

(b) What is benchmarking? Classify benchmarking based on the

nature of firms against which benchmarking could be done.

4. (a) Why are teams important in TQM? How should teams be

structured?

(b) Describe some work practices that can promote learning in

the context of TQM.

5. What are the principal concepts of ISO 9000 QMS? How does the implementation of the system encourage transparency and accountability?

SECTION B

6. Please read the following case study carefully and answer the questions given at the end:

TQM Implementation

Occasion: A 4-day seminar on TQM: Concepts & Practices, orhanised

by Quality & Productivity Services (QPS), Mumbai.

Date: August 14, 1998

Time: 2 p.m.

Venue: The Orchid Room, The Grand Holiday Hotel, Mumbai.

Present: S.P. Kumar, CEO, QPS; Mahavir Shah, Guest Speaker,

Participant.

Kumar: Welcome to the Day 3 post-lunch session. We have had a beneficial interaction during the last two-and-a-half days. It is evident from the feedback that I have gathered that you are raring to get back to your workplaces to implement Total Quality Managaemnt (TQM). But therein lies the crux of the issue: implementation is never easy. One has to be careful and cautions; it is the first few months that make all the difference to the success of an organisational transformation like TQM. Unloading the damage would take a larger portion of managerial time than actual implementation. Therefore, I thought it necessary to focus half a day of this seminar on this critical aspect. The best way to go about it is to listen to the experiences of a company -- and an individual --- who has just gone through that phase. Ladies and Gentlemen, please welcome Mahavir Shah.

Mahavir is a well-known Human Resources (HR) professionals; he has illustrious track0record. He has been Vice-President (HR) at the Rs. 380-crore Madhusudan Chemicals Ltd. (MCL) for the last 5 years. Last year, when his company decided to go in for TQM, he was given an additional responsibility by his managing director, and appointed the company's TQM Co-ordinator. He has been rather reluctant to speak about TQM. In fact, when I invited him over, he requested me to permit him to speak about the birth-pangs of TQM, rather than its impact. That, he said, was far more important since it was relevant to the Indian context. So, Mahavir will talk about his experiences in implementing TQM. Mahavir, the floor is yours.

Shah: Thanks, Kumar, Let me mention at the outset ladies and gentleman, that I would like this to be an interactive session. Please feel free to interrupt me with your questions and comments. I am glad to know that you're all keen on implementing what you have learnt here. But let me warn you; things may look rosy in a seminar hall, but reality is different. You have to deal with too many variables and contingencies. What makes the task even more challenging is the fact that there is no tired-and-tested TQM formula, which can be uniformly applied to all the companies. The experience of each company is unique since the TQM route-map is different. But why is that so? Because the context is dissimilar. Yes?

I would beg to differ with you. My organisation is embarking on a TQM programme, and we are putting together the common factors necessary to drive such a change initiative. We have identified them after visiting quite a few organisations in the country……..

There may be certain fundamental issues, but the context on which a change is effected is crucial. You are bound to experience that when you actually begin implementing TQM in your organisation. We could discuss that as we go along, but let me mention 4 common factors straightway, First, TQM should have a link with corporate strategy. It should be rooted in at least 2 or 3 of the company's satisfaction and product differentiation. When it operates in a vacuum --- as a standalone activity --- you can never achieve improvements in business results, which is the raisan d'etre of TQM.

Second, TQM is a team effort --- not an individual initiative. A co-ordinator, by himself, would not be able to achieve anything. This is where his skills in directing disparate individuals in an organisation towards a common cause come handy. Third, TQM must link value-addition to the customer. Without the linkage, it will only yield incremental improvements in the company's processes. It would not lead to geometric leaps in business results that a well-designed TQM can invariably provide. And, final, TQM needs the personal involvement and support of the CEO. Without that, it can never gain credibility in the entire organisation In fact, this is the most importance issue, which should be addressed night at the beginning of the implementation phase.

I mentioned business context earlier, Let me, therefore, spend a few minutes discussing the nature of our business at MCL so that we understand TQM in the right perspective. For decades, MCL has been known as a caustic soda company --- a perception that's bound as a change soon. The imperatives of value addition and the nature of our production processes are forcing us to change tack. Today, our 13 per cent marketshare makes us the second-largest producer of caustic soda in our country. Our manufacturing facilities are located at Vadodara, a city located in our main market. Gujrat which consumers over 60 per cent of our production.

I wouldn't like to brother you with technical details but caustic soda, as some of you may be aware, is obtained by the electrolysis of salt --- a process which also yields chlorine as a by-product. The ratio of caustic soda is usually 1:5:1, the combination is termed as an Electro-Chemical Unit(ECU), Caustic Soda and chlorine, incidentally, have separate markets. Paper, Aluminum, Textiles, and Soaps & Detergents are caustic soda's primary user-industries; chlorine is sold mostly to petrochemical units. They convert chlorine into ethylene dichloride or a vinyl chloride monomer, which us used to produce Poly-Vinyl Chloride (PVC) which, in turn, is used in the manufacturer of plastics. As you see, the scope for value-addition lies in the chlorine component of an ECU. Surely, the price-realisation of an ECU is higher when there is greater emphasis on chlorination. But an increase in demand for chloride leads to glut in caustic soda. Yes, sir?

Isn't there a glut in the caustic soda capacity in the country? Did that compel you to embrace a TQM programme?

There is an oversupply of caustic soda. Against a demand of 1:10 million tonnes per annum (tpa), the current capacity in the country stands at 2.20 million tpa --- not to mention the licenses issued for another 1 million tpa. With most producers operating at a 50 per cent capacity, the situation is bad. For, caustic soda is a commodity business, where volumes are crucial; so, capacity utilisation is a critical parameter of profitability and cost-effieciency. Of course, MCL has some advantages. It has captive salt words, which meet 75 per cent of its requirements of sodium chloride, the main raw material, And it has an in-house power generation facility which offers power at Rs. 2.60 per unit against Rs. 4.70 from the state power grid. Naturally, since power constitutes 67 per cent of the cost of production, we are able to save a lot of money….

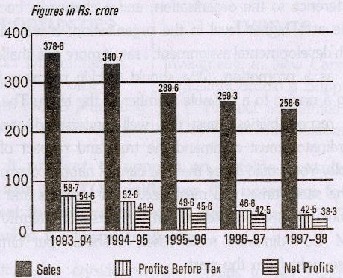

MCL's FINANCIAL

Did you find it difficult to get accepted within the organisation? How can a co - ordinator elicit the support of the entire organisation?

I will come back to cost savings later. The question raised by the gentleman to my left, I think, is far more important. The immediate priority for a TQM Co-ordinator is to establish his personal credentials in the organisation. Self-evaluation through a personal SWOT marks the first step. This is necessary even when the co-ordinator is an old band in the organisation. For instance I had began with MCL for over a decade, and was familiar with all the people in the organisation. But, much to my surprise, immediately after I took on the new responsibility. I felt like a new kid on the block. It was, of course, a momentary reaction. After all, there were new working relationships to be forged and new expectations to be met.

I was aware that this was a splendid break for me, a wonderful learning experience, an opportunity to make a difference to the organisation, and a chance to become visible at a higher level in the organisation. It was also a tough developmental assignment. I saw it more as a challenge than as a promotion, One should quickly progress from being a novice to a valuable member of the team. The role and responsibilities must be well understood, and a co ordinator must command the trust and respect of the people. You would agree that this couldn't happen overnight. At the same time, you must heed your instincts and stick to your principles, A reputation for personnel integrity is a TQM Co-0ordinator's main asset; it should put him on coupe right from the start.

Establishing one's credentials is also an effective way of neutralizing the effects of what I call Total Quality Paralysis (TQP), which is a common phenomenon during the initial phase of TQM. Since the TQM processes are unique to a specific context, there is usually no guidance on how to get started. What is characteristic of TQP is that while a lot of people know something about TQM, nobody does anything. Everyone talks about TQM, but nobody can get the process-improvements going. This happens even as the co-ordinator is trying to establish clear guidelines on how to get the process off the ground and how to sustain the momentum thereafter….

| STRENGTHS | WEAKNESSES |

Formidable Market Presence Captive Power Plant Proximity To Customers Backward Integration |

Limited Product Portfolio Oversupply In Industry Low Capacity Utilisation Little scope For Branding |

| OPPORTUNITIES | THREATS |

Product Differentiation Brand Building Entry Into FMCG Marketing Higher Price Realisations |

Investments In New Capacities Quality–Conscious Suppliers Product Substitutes Cost–Conscious Customers |

Isn't it prudent to appoint an outside consultant who can give TQM initiatives the necessary focus and set the ball rolling in the right direction? That was what we learnt yesterday…

Essentially, an outside consultant helps to sell TQM to senior management. That is a formidable contribution to the implementation phase, and a great help to the in-house co-ordinator. But MCL did not appoint an outsider, we enlisted the services of several trainers who, in turn, were assisted by in house facilitators. It is not unusual for people to go off the track, resulting in hiccups of various kinds, in the early phases. A TQM Co-ordinator must structure his quality initiatives in such a way that they run simultaneously, not sequentially

Phase I consists of organisational self-evaluation. This can be done either by the co-ordinator personally if he feels that the top management needs to be enlightened on TQM, or he could involve senior managers in several brainstorming sessions. Basically, you must seek answers to the following questions:

- Where are we now as on organisation?

- Where do we want to go from here?

- How do we get there?

- How will get us closer to our goals?

- How will TQM get us closer to our goals?

- How will we know when we get there?

The last question, in my view, is vital because it will provide you with the necessary yardsticks to evaluate performance. It is the co-ordinator's responsibilities to ensure that systematic procedures for determining and fulfilling quality goals are down in a manner which is understood by all. Transparency is importance. The objectives of Phase I are two fold: constructing a Quality Model: and identifying the opportunities For Improvements (OFI).

Phase II, which runs parallel to phase I, consists of educating the members of the senior and middle management about TQM. This is best achieved by having 2 one-day seminars for small groups of managers with a month's gap between each. The gap is necessary so that manager's come prepared with proposals for quality goals and policies. It is important to have no more than 25 senior and middle managers in each group. In my organisation, which has as many as 750 managers, Phase II ran for 3 months. An important exercise that must be conducted during this phase is to classify quality improvements into internal and external changes. Initial improvements should deal with internal changes because the results would be tangible and evident.

Phase III is a critical phase because it is here that the management has to decide whether drastic changes ---- we called them breakthroughs --- are required. It is important to hear in mind that all revolutions originate in a crisis. A crisis is an unacceptable gap between the current and the desired situation. It takes a crisis for the top management methods even though they had served well in the past.

Let me mention a related issue here. TQM often snaps the various established linkages in a business system, For instance, let us suppose that, through TQM, you are able to reduce your inventory lead-time from 8 weeks to say, 6. This will impact raw-material delivery, whose frequency will now increase. So will the number of purchase-orders made during a particular period. If purchase costs are being allocated on the number of orders raised the new development might place the system of cost appointment out of gear. If people do not understand these linkages, they are bound to attribute all kinds of distortions to TQM even when they have no bearing on it, Yes, sir?

During the last 2 days of the seminar, speakers emphasized on the necessity to have a change-drive within the organisation. Did you feel the need for a change-driver?

Yes, I TQM initiative can succeed only when it is rooted in a change-driver, which provides a compelling, need for change. It could be a vision that is just out of radically new thinking is applied. It could be some signs of decline within the company; it could be the fact that competition is closing in on you; or it could be dictated by the market-leader's extra ordinary performance. If people do not see a fundamental reason for change, the TQM Co-ordinator's commitment, however genuine, may be discounted by them as one person's eccentricity. The change-driver must outweigh the costs of transition and the uncertaintly, that will set in….

Can you will us what the change-driver was at MCL?

For decades, MCL has been in the commodity business. But the supply overhang in the caustic soda industry has forced us to look for alternative growth routes. We have taken 2 critical measures: consumer marketing and value-addition. We are increasing our salt-works capacity not only to meet 100 per cent of our raw material requirements from within, but to market branded salt to domestic consumers as well. This is a new area for us, and a paradigm shift in our conventional approach to marketing. Historically, we have always looked at chlorine as a byproduct. With opportunities for value addition opening up in the chlorine segment --- thanks to massive additions to petrochemical capacities in the country --- our new thrust is to look for ways in which MCL can add value to our customers supply chain. That calls for a different marketing approach in which customer requirements, both current and future, become the focal point of all that we do. We asked overselves: what would happen if we did not venture into these 2 areas? The answer was that, sooner or later we would be wiped out of business. That was the change-driver.

At the same time, we had ascertained the factors crucial to the success of the organisation. These vary from one company to another. For instance, in our case, it was the make-to -market time which was important. Unless we address that, we will fail in our efforts to serve the customer. So, we have benchmarked the make-to-market time with the industry leader. At 3 weeks, it is well ahead of our own cycle-time of 6 weeks. We have a lot of catching up to do….

TQM entails bringing disparate individuals together. But how do you handle opposition --- which is bound to exist at various levels ---- to a change initiative?

For a co-ordinator, the change process is his world. It is his reason for being. But to everyone else in the organisation, TQM is just one of the many issues, They will support the change process if he helps them to achieve their goals. A co-ordinator should link the change process to his colleagues' larger concerns so that it becomes a means for achieving their goals and enables them to perceive TQM as an initiative that not only helps the entire organisation, but also benefits them individually. This is the most difficult part of the work of a co-ordinator. Staying focused often becomes difficult.

In my experience, people fall into 3 categories as far as their response to change is concerned. You have those who declare their opposition to the programme. It is easier to deal with them once you identify, and proceed to address, their concerns. If someone says, "This quality programme is similar to what we have done before. They are just feel-good exercises that take us nowhere," don't jump to the defence of your programme. Don't interpret it as a personal attack. You need to find out why he feels that way, and what he really means. It is very likely that he understands the magnitude of the change programme but fears that everyone wants only a cosmetic exercise. They become convinced of the compelling need for chance once you address What-is-IT-For-Me? Factor, And you have those who offer instant support, which is a façade. It is this category you should be wary of. To be successful in his pursuit, a TQM Co-ordinator should never be afraid of, nor feel apologetic about, asking something that he does not know. An honest and open approach usually neutralises potential opposition. Handholding makes the journey together worthwhile. What can consume a co-ordinator's time is his search for volunteers. I found that candid people make food candidates. I particularly targeted the champions of previous improvement programmes at MCL. They are the people with courage, motivation, and exercise, who can make a TQM initiative a success. They love to have another chance at making change happen with management support and proper tools and training. My experiences with people have taught me not be attribute past failure to individuals and their shortcomings.

How about the CEO's support? How do you secure it?

The TQM Co-Ordinator's primary task is to sustain the CEO's sponsorship of the change process. It should be possible, in time, to secure the collective sponsorship of the entire organisation, but everything hinges upon the leader's personal resolve. It is the co-ordinator's job to protect the CEO from needles surprises and embarrassments even as he struggles with they TQM concepts. You should ensure that the president personally chairs all meetings of the Quality Council…

What should be the structure of a TQM Council? Should it be headed by the CEO or the co-ordinator?

The Central Council should be headed by the CEO. Even when the CEO delegates most of the day-to-day activities pertaining to TQM to the co-ordinator, he should personally chair the meeting of the Council. The CEO may be unable to devote much time to TQM not only because of other demands on his time, but because he is unsure of what is expected of him. This is a common failing in most companies. In fact, a CEO could be as unfamiliar with the concepts of TQM as others in the organisation. The co-ordinator should secure the CEO's total commitment and ensure that the latter does not lose interest in TQM. So, it is necessary to establish a proper working relationship with the CEO. The Central Council must be supported by Functional of Departmental Councils. Their composition --- which, like the Central Council, should ideally be cross--functional ---- must be linked to the specific requirements of the OFI.

Questions:

(a) What are the majors issues that a TQM co-ordinator must

deal with during the implementation phase? What pitfalls should

be guard against? Are there certain ground rules he should establish

in his relationship with colleagues and subordinates to set

the momentum for change?

(b) What are the value activity he should monitor to ensure

that his quality initiative is working? How should be link TQM

to the employees larger concepts and customer satisfaction?